Engineers at the Massachusetts Institute of Technology (MIT) have developed new ultrathin fabric solar cells that can quickly and easily convert any surface into a power source.

These resilient, flexible solar cells are attached to a sturdy, lightweight fabric and are much thinner than human hair, making them simple to mount on a fixed surface. They can be transported and quickly deployed in remote regions to provide assistance in an emergency or they can provide energy on the fly as a wearable power fabric. They are created of semiconducting inks utilizing printing techniques that can be scaled up in the future to large-area manufacturing and generate 18 times more power per kilogram than conventional solar panels.

These solar cells may be laminated onto many different surfaces because they are so light and thin. For example, they could be affixed to tents and tarps that are used in disaster recovery operations, integrated onto a boat’s sails to give power while at sea, or used on drone wings to increase their flying distance. This portable solar technology requires minimal installation and is simple to integrate into built environments.

Traditional silicon solar cells on the other hand must be wrapped in heavy, thick aluminum framing because they are fragile, which restricts where and how they may be used.

How ultrathin lightweight solar cells are made

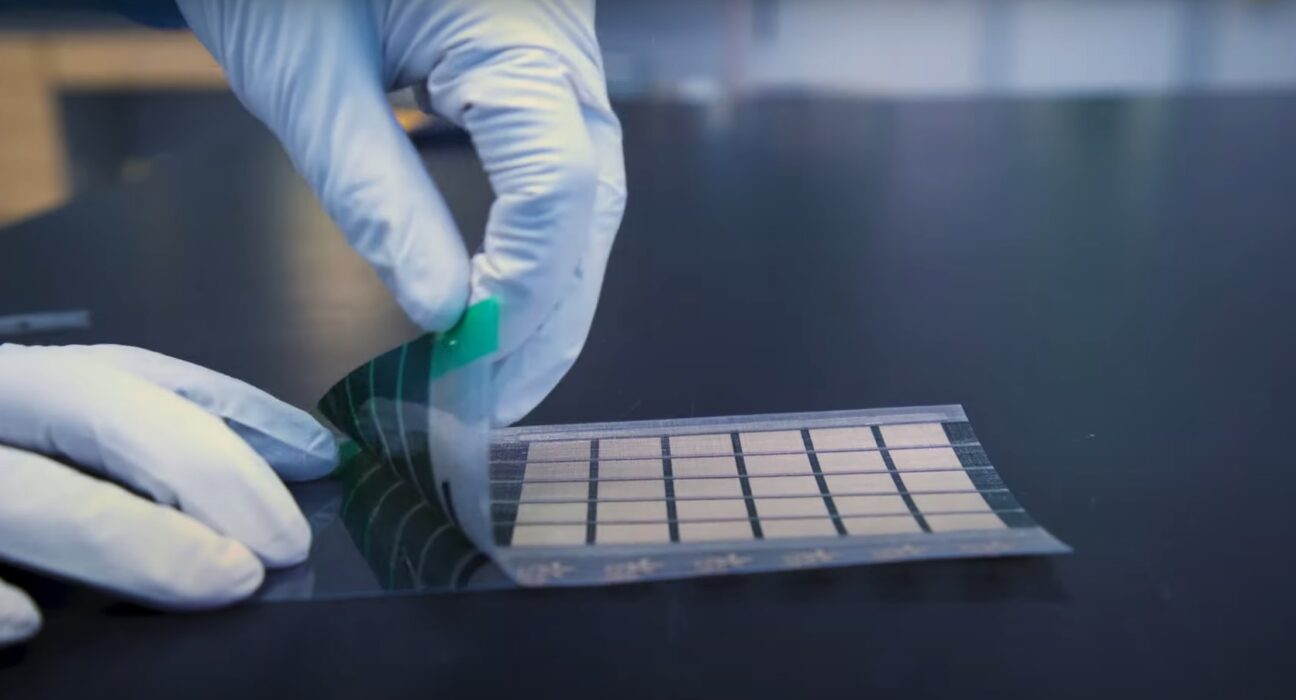

Nanomaterials in the form of printable electronic inks are used to make solar cells. They use a slot-die coater, which deposits layers of the electronic materials onto a ready, releasable substrate that is only 3 microns thick, to coat the solar cell structure. To finish the solar module, an electrode is deposited on the structure using screen printing (a process similar to how graphics are added to silkscreened T-shirts). The printed module, which is roughly 15 microns thick, may then be peeled away from the plastic substrate to create an ultralight solar device.

However, such tiny, freestanding solar modules are difficult to deploy since they can be easily torn and difficult to manage. The MIT team looked for a thin, flexible, and strong substrate to which they could attach the solar cells in order to overcome this difficulty. Fabrics were chosen as the best option since they offer mechanical resilience and flexibility with minimum additional weight.

They discovered the perfect substance: Dyneema, a composite fabric with a weight per square meter of just 13 grams. The fibers used to make this fabric are so powerful that they were used as ropes to lift sunken ships from the bottom of the sea. They affix the solar modules to sheets of this fabric by putting a thin coating of UV-curable glue on top of it. This results in a very thin and durable mechanical solar structure.

“While it might appear simpler to just print the solar cells directly on the fabric, this would limit the selection of possible fabrics or other receiving surfaces to the ones that are chemically and thermally compatible with all the processing steps needed to make the devices. Our approach decouples the solar cell manufacturing from its final integration,” the authors of the paper explain.

The new technology put to the test

The invention could produce 730 watts of power per kilogram when it was freestanding and roughly 370 watts per kilogram when it was mounted on the high-strength Dyneema fabric. This is nearly 18 times more power per kilogram than traditional solar cells.

“A typical rooftop solar installation in Massachusetts is about 8,000 watts. To generate that same amount of power, our fabric photovoltaics would only add about 20 kilograms (44 pounds) to the roof of a house,” the authors say.

Additionally, they put their products through a durability test and discovered that even after rolling and unrolling a fabric solar panel more than 500 times, the cells still maintained more than 90% of their original power-generating capacities.

Even though their solar cells are significantly lighter and more flexible than conventional cells, they would still require an additional substance to shield them from the elements. The cells’ performance could be negatively impacted by interactions between the carbon-based organic material used to create them and oxygen and moisture in the surrounding environment.

“Encasing these solar cells in heavy glass, as is standard with the traditional silicon solar cells, would minimize the value of the present advancement, so the team is currently developing ultrathin packaging solutions that would only fractionally increase the weight of the present ultralight devices. We are working to remove as much of the non-solar-active material as possible while still retaining the form factor and performance of these ultralight and flexible solar structures. For example, we know the manufacturing process can be further streamlined by printing the releasable substrates, equivalent to the process we use to fabricate the other layers in our device. This would accelerate the translation of this technology to the market” the authors of the study concluded.

Vladimir Bulović, the Fariborz Maseeh Chair in Emerging Technology, leader of the Organic and Nanostructured Electronics Laboratory (ONE Lab), and director of MIT.nano, was the senior author of the paper describing the work. Co-lead authors were Mayuran Saravanapavanantham, an electrical engineering and computer science graduate student at MIT; and Jeremiah Mwaura, a research scientist in the MIT Research Laboratory of Electronics. The research was recently published in the journal Small Methods.